Categories

Tags

-

#Drum Pilling Tester Operation Process and Precautions

#Bag Loading Machine Supplier: Creating Efficient and Accurate Packaging Solutions

#From Wardrobe to Suitcase: Multi Scenario Application of Yibo Clothes Dust Cover

#The Role of Changhong Precision in Injection Molding Manufacturing Processes

#SLENERGY Intelligent Energy Management Platform: Efficient Energy Saving

#Smart Life

#Large Flow Low Noise Blower: The Silent Revolution in the Industrial Field

#Industrial Field: The Importance and Application of SWT Automatic Backup Generators

#The Importance and Challenges of Plastic Pigments in Industry

#The Brush Mower Helps with Farmland Management

#Improves Efficiency and Environmental Protection

#High Quality Fit for TOYOTA 4K-E Piston Rings: Balancing Durability and Performance

#Application of Tube Skid Container in the Energy Industry

#The Role of Rail Dowels in Preventing Track Deformation and Ensuring Safety

#Application of Recyclable Materials in Shaped Spout Pouches

#Real-Time PCR Analyzer: A Powerful Tool for Real-Time Monitoring of Gene Expression

#The Performance and Practicality of Power Puzzle DS1601H

#Exploring the Advantages and Applications of Sea-Rail Service

#Green tea / cotton yarn

#Improving Efficiency: Advantages of Spiral Tunnel Ice Cream Machine

#Paging Labeling Machine Helps Enterprises Achieve Intelligent Packaging Upgrade

#How 4-Way Priority Valve Controller Can Improve Industrial Automation Efficiency

#Revolutionizing Gas Metal Arc Welding (GMAW): Advanced Welding Positioner Integration for Enhanced Productivity

#Wuxi Bluemann Made a Brilliant Appearance at SNEC PV+2025

#And the Exhibition Came to a Successful Conclusion

#Lightweight and Sturdy: Advantages of Aluminum Alloy Camera Hou

#Customized OEM Milling Cutter Bar: Meeting Diverse Machining Needs

#Yuantai Provides Clean Energy for Somalia: Transportation of Solar Photovoltaic Panels

#ELP Global Shutter USB Camera Module

#Suitable for Multiple Platforms

#DPA Paint Mist Filter Cotton / DPA Paint Mist Filter Bags

#Performance and Advantages of BAN Panel Air Filter

#Wash out Personality: Diversified Functions of Professional Denim Washing Machine

#Incubator for Water Analysis: A Tool for Accurately Controlling Water Quality Safety

#Exploring the Diversity and Applications of LED Indicator Lights

#Analysis of Technical Characteristics and Advantages of Side Plate Vibration Motor

#New Choice for Architectural Lighting: Advantages and Applications of Construction Light Tower Generator

#Low Vibration Brushless Adjustable Fan: Technology Saves Energy

#Brings Fresh Fashion to Life

#Iron Zinc Chrome Brown: A New Material to Improve Coating Durability

#Lightweight Vacuum Cleaner Travel Vac B-C: A New Choice for Cleaning During Travel

#Revolution in the Pharmaceutical Industry: Advantages Brought by Automatic Labeling Machines

#Celebrating Dragon Boat Festival

#HENGXING Joins Hands to Share Traditional Culture

#Advantages and Applications of Excavator Universal ClawWeld

#Electrostatic Filter Cotton: Technical Overview

#Inspectores de la Provincia de Jiangxi Visitan Sanxin Medtec Co.

#Ltd y Llevan a Cabo Actividades de Formación Práctica in Situ Sobre Productos Sanitarios

#Discover the Advantages of Pre-Made Packaging: Saving Time and

#Anti-Static Filter Cotton: Comprehensive Technical Specification

#Newgear Intelligent Transmission Honored with "Annual Benchmark Product" at 2024 GGII Humanoid Robot Golden Ball Awards

#Automatic Counting Scales: Efficient and Accurate Counting Solutions

#Portal Stacker Reclaimer: Key Equipment to Improve Material Handling Efficiency

#Exploring the Application and Advantages of Sliding Clam Grapple

#Strong Overseas Demand Brings New Opportunities for Export China SUV Project

#ltra-Precise HSK-C Tool Shank for High-Performance Milling

Archives

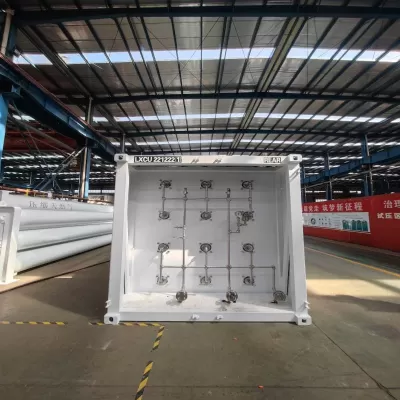

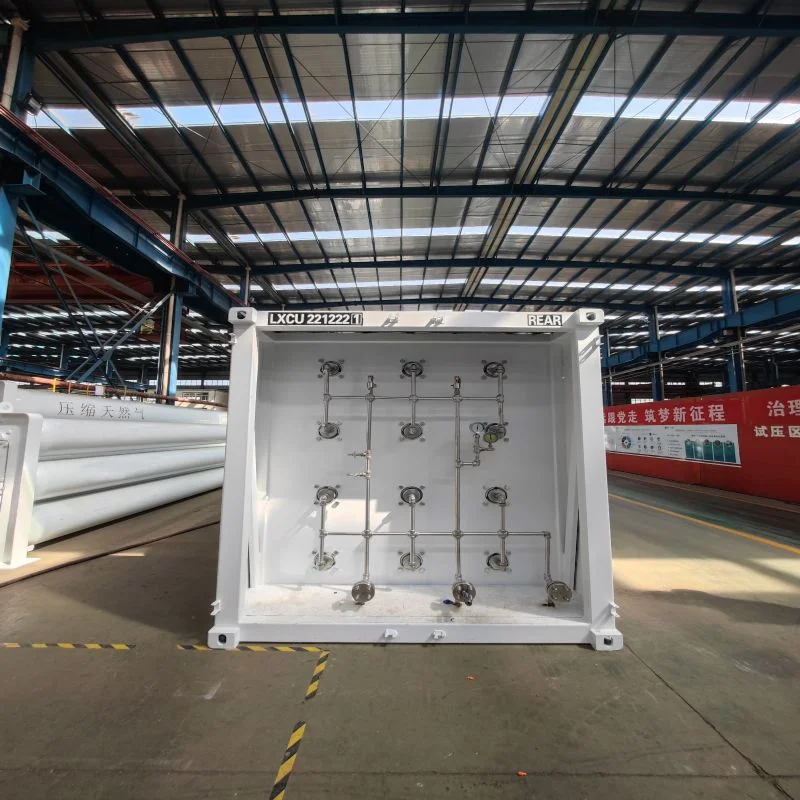

Application of Tube Skid Container in the Energy Industry

-

Posted by wang july Filed in Other #Application of Tube Skid Container in the Energy Industry 279 views

The energy industry, encompassing sectors such as oil and gas, renewable energy, and power generation, faces unique challenges in terms of equipment transportation, installation, and maintenance. Among the various solutions available, tube skid containers have emerged as a versatile and efficient tool. These containers offer a modular, compact, and robust solution for housing and transporting sensitive equipment, ensuring safe and efficient operations across diverse energy sectors.

Oil and Gas Exploration and Production

Enhanced Mobility and Durability

In remote and harsh environments typical of oil and gas exploration, equipment must be robust, easily transportable, and capable of withstanding extreme conditions. Tube skid containers provide a perfect fit, offering a rugged frame that protects sensitive drilling equipment, pumps, and control systems from vibrations, shocks, and environmental exposure. Their modular design allows for easy disassembly and reassembly, facilitating rapid deployment and relocation.

Cost-Effective Solutions

Moreover, tube skid containers reduce operational costs by minimizing downtime. Their durability ensures that equipment remains functional for longer periods, reducing the need for frequent repairs or replacements. Additionally, the containers' compact design optimizes space utilization on offshore platforms and drilling sites, enhancing operational efficiency.

Renewable Energy Projects

Supporting Solar and Wind Installations

The renewable energy sector, particularly solar and wind power, benefits significantly from tube skid containers. In solar farms, these containers house inverters, transformers, and battery storage systems, protecting them from weather elements and facilitating easy access for maintenance. Similarly, in wind farms, tube skid containers are used to transport and store turbines' control systems, generators, and other critical components.

Streamlined Logistics and Installation

The modular nature of tube skid containers streamlines logistics, enabling faster and more organized installation processes. This is particularly crucial in large-scale renewable energy projects where timely deployment of equipment can significantly impact project timelines and budgets. Furthermore, the containers' ability to withstand extreme weather conditions ensures that operations can continue uninterrupted, even in adverse weather scenarios.

Power Generation and Distribution

Safe Transportation and Storage of Electrical Equipment

In power generation plants and distribution networks, tube skid containers play a vital role in the safe transportation and storage of electrical equipment. Transformers, switchgear, and other high-voltage components are often housed in these containers, which provide a secure, controlled environment that protects against moisture, dust, and temperature fluctuations.

Facilitating Maintenance and Upgrades

The containers' modular design also facilitates maintenance and upgrades. Electrical components can be easily accessed and serviced without disrupting the overall power supply, minimizing downtime and ensuring continuous operation. This is particularly important in critical infrastructure, such as hospitals and data centers, where uninterrupted power supply is paramount.

Customization and Adaptability

Tailored Solutions for Specific Needs

Tube skid containers' adaptability allows them to be customized to meet the specific needs of different energy industry applications. Manufacturers can design containers with specific dimensions, materials, and configurations to accommodate a wide range of equipment and operational requirements. This customization ensures that the containers provide optimal protection and functionality, enhancing overall project success.

Integration with Advanced Technologies

As the energy industry increasingly adopts advanced technologies, such as automation, IoT, and AI, tube skid containers can be integrated with these systems to enhance monitoring, control, and data collection. Smart sensors and communication devices can be installed within the containers, providing real-time insights into equipment performance and operational status, enabling proactive maintenance and decision-making.

Conclusion

Tube skid containers have revolutionized equipment handling in the energy industry, offering a robust, modular, and cost-effective solution for transportation, installation, and maintenance. Their ability to withstand harsh conditions, optimize space utilization, and streamline logistics makes them indispensable in diverse energy sectors, from oil and gas to renewable energy and power generation. As the industry continues to evolve, Huani Metal Material tube skid containers will play an increasingly critical role in ensuring safe, efficient, and sustainable operations. By leveraging their benefits and adapting them to specific needs, energy companies can enhance their operational performance and drive innovation in the sector.

http://www.huanigroup.com/application-of-tube-skid-container-in-the-energy-industry.html