Chongqing Huigong Machinery Manufacturing Co., Ltd. specializes in producing aluminum honeycomb panels—versatile, high-performance decorative materials designed for both aesthetic and functional needs across industries. As a key product in the company’s decorative wall panel lineup, these panels blend durability, lightweight design, and customization, making them suitable for diverse applications from building exteriors to interior decor. For detailed specifications, customization options, and quotation inquiries, visit the official

Chongqing Huigong Aluminum Honeycomb Panel page.

Founded in 2012, Chongqing Huigong is an integrated industry-trade enterprise with a 15,000-square-meter factory, over 100 employees, and over a decade of experience in decorative building materials. Beyond aluminum honeycomb panels, its product portfolio includes WPC panels, SPC panels, and fireproof boards—positioning the company as a one-stop supplier for interior and exterior decoration needs. With export capabilities and strict quality control, the company caters to both domestic and international clients, adhering to global standards for safety and performance.

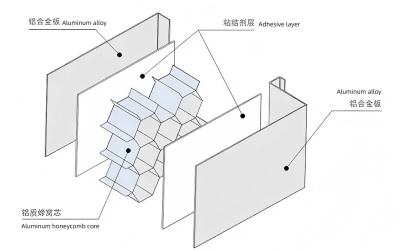

Chongqing Huigong’s aluminum honeycomb panels feature a sandwich structure optimized for strength and lightness, consisting of three key components:

- Surface Panels: Made of high-quality aluminum alloy sheets (typically 1100, 3003, or 5052 series), available in various thicknesses (0.8mm–3mm) and finishes. Common finishes include electrostatic spraying, fluorocarbon coating, and wood grain transfer—catering to different aesthetic preferences (e.g., metallic, matte, or natural wood looks).

- Honeycomb Core: The middle layer is an aluminum honeycomb structure, with cell sizes ranging from 5mm to 20mm. This hexagonal design distributes pressure evenly, enhancing the panel’s load-bearing capacity while minimizing weight.

- Adhesive Layer: Uses high-strength, weather-resistant structural adhesives (e.g., epoxy resin) to bond the surface panels and honeycomb core. The adhesive ensures long-term stability, even in extreme temperature or humidity conditions.

Chongqing Huigong’s aluminum honeycomb panels stand out for their balanced combination of performance and practicality, with advantages that address industry pain points:

- Lightweight Design: Compared to traditional solid aluminum panels or stone materials, aluminum honeycomb panels are 30%–50% lighter. This reduces structural load on buildings, simplifies transportation and installation, and lowers overall project costs.

- High Strength & Durability: The honeycomb core’s hexagonal structure provides excellent compressive, bending, and impact resistance. The panels maintain shape and integrity even under heavy loads, with a service life of 15–20 years when properly maintained.

- Fire & Weather Resistance: The panels meet Grade A1 fire resistance standards (non-combustible), making them suitable for high-rise buildings, public spaces, and areas with strict fire codes. They also resist corrosion, UV radiation, and moisture—performing well in outdoor environments (e.g., building facades) or humid indoor spaces (e.g., bathrooms, kitchens).

- Thermal & Sound Insulation: The air-filled honeycomb core acts as a natural insulator, reducing heat transfer (improving building energy efficiency) and blocking noise. This makes the panels ideal for offices, hotels, and residential spaces where comfort is a priority.

- Easy Installation & Maintenance: The panels are prefabricated to custom sizes, supporting quick on-site installation (e.g., dry hanging or bonding). Their smooth, non-porous surface resists dirt and stains, requiring only regular wiping for maintenance.

Thanks to their versatility, Chongqing Huigong’s aluminum honeycomb panels are used across multiple sectors:

- Building Facades & Curtain Walls: Lightweight yet strong, they are a popular choice for high-rise building exteriors, offering weather resistance and customizable aesthetics.

- Interior Decoration: Applied to wall cladding, ceiling panels, and partition walls in offices, hotels, shopping malls, and luxury homes. Wood grain or marble finishes add a high-end look without the cost of natural materials.

- Furniture & Cabinetry: Used for cabinet doors, table tops, and wardrobe panels—combining durability with a sleek, modern appearance.

- Transportation: Suitable for interior panels of high-speed trains, yachts, and RVs, where weight reduction and durability are critical.

- Public Infrastructure: Used in subway stations, airports, and exhibition centers, thanks to their fire resistance and easy maintenance.

Chongqing Huigong ensures consistent quality and production capacity through advanced manufacturing and strict testing:

- Automated Production Lines: The factory uses imported equipment for panel cutting, bonding, and finishing, with over 80% of processes automated. This ensures uniform dimensions, precise adhesive application, and consistent finish quality.

- Raw Material Control: Sources high-grade aluminum sheets and adhesives from certified suppliers, with pre-production testing to verify material strength and weather resistance.

- Certifications & Testing: Products pass ISO9001 (quality management) and ISO14001 (environmental management) certifications, as well as SGS testing for fire resistance, corrosion resistance, and load-bearing capacity. Each batch of panels undergoes (sampling) inspection before delivery.

Chongqing Huigong provides end-to-end support to meet client needs:

- Customization: Offers tailored solutions for size (max width up to 1.5m, length up to 6m), thickness (total thickness 5mm–50mm), finish (color, texture), and hole punching (for special installation needs).

- Pre-Sales Support: Professional teams provide technical consultations, material samples, and design suggestions to help clients select the right panel specifications for their projects.

- Logistics & Installation: Collaborates with reliable logistics partners for safe, on-time delivery. Provides detailed installation guides and on-site support if needed.

- After-Sales Guarantee: Offers a warranty period (typically 5 years) for manufacturing defects, with a dedicated team to address post-purchase issues.

- What is the minimum order quantity (MOQ)?

No MOQ for standard finishes and sizes; custom orders may require a minimum quantity based on production efficiency.

- How long is the production lead time?

7–15 working days for standard orders; 15–25 working days for custom orders (depending on complexity).

- Can samples be provided?

Yes, free samples are available for quality verification; clients cover express delivery fees.

- What is the panel’s maximum size?

Customizable up to 1.5m (width) × 6m (length); larger sizes can be discussed for bulk projects.

Chongqing Huigong’s aluminum honeycomb panels offer a balance of performance, aesthetics, and practicality, making them a versatile choice for decorative and structural applications. With advanced production, strict quality control, and customizable solutions, the company caters to diverse industry needs—from building exteriors to high-end interiors. For more details on pricing, technical specifications, or order placement, visit

Chongqing Huigong’s Aluminum Honeycomb Panel official page.