Is Air Expandable Shaft changing production thinking at Cbbmach

-

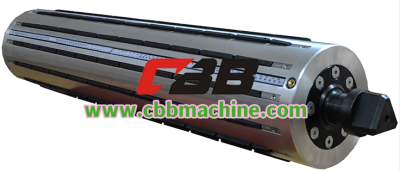

In manufacturing settings that value balance and control, the Air Expandable Shaft from Cbbmachine represents a composed approach to roll handling, emphasizing steady grip through pneumatic responsiveness rather than mechanical force. This solution is aimed at operations that seek continuity, clarity, and confidence across daily tasks, without relying on dramatic claims or overstated promises.

Material handling often defines the rhythm of a production line. When rolls are mounted and released repeatedly, smooth engagement becomes essential to maintaining focus and order. An air based expansion mechanism supports internal contact with the core, encouraging even pressure distribution and controlled rotation. This interaction allows materials to move with intention rather than resistance, creating a sense of flow that operators quickly appreciate.

Adaptability has become a quiet requirement in modern facilities. Product variations, changing schedules, and evolving processes all demand equipment that responds without complication. A shaft that expands through air pressure adjusts naturally to different core conditions, reducing the need for constant recalibration. This responsiveness supports faster transitions and encourages teams to remain flexible without feeling rushed.

Ease of use plays a meaningful role in sustaining long term efficiency. When mounting procedures feel intuitive, physical strain is reduced and attention can remain on accuracy. Operators benefit from a calmer working experience, where actions feel deliberate rather than forced. Over time, such ease contributes to steadier output and a more composed production environment.

Consistency is another understated advantage. Repeated expansion and release require internal structures that maintain shape and responsiveness through regular use. Thoughtful design and material selection help ensure that performance remains predictable, allowing teams to trust the equipment as part of their routine rather than treating it as a variable.

Integration within existing systems further enhances practical value. A well considered shaft design fits into established machinery without demanding disruptive changes. This compatibility allows manufacturers to refine specific elements of their process while preserving familiar workflows. Incremental improvement often proves more sustainable than sweeping alteration.

Beyond the physical component, there is importance in clarity of communication. Clear guidance, practical documentation, and a sense of shared understanding support confident application. When users feel informed rather than overwhelmed, implementation becomes smoother and long term cooperation feels natural.

In an industrial landscape shaped by constant adjustment, progress is often the result of thoughtful choices rather than bold gestures. Selecting components that quietly support stability, adaptability, and ease of operation can influence daily performance in subtle but lasting ways. These decisions help shape how a facility responds to change while maintaining its sense of order.

If this measured perspective on production resonates with you, let your curiosity take a purposeful turn toward https://www.cbbmachine.com/news/industry-news/what-is-an-air-expandable-shaft-in-the-converting-industry.html , where thoughtful engineering invites a closer look and a rewarding click.