water wheel rotary transfer machine processing problems, which

-

water wheel rotary transfer machine processing problems, which way to disassemble and repair it? In the previous article, we learned about "How to disassemble 6150 CNC lathe? What should I pay attention to?" In the previous article, we said that the CNC lathe should pay attention to the content in disassembly, the content of this article is to explain in detail what way we should use to disassemble the water wheel rotary transfer machine after the processing problem, which is on the basis of not damaging the machine tool. The disassembly methods mainly include hammer unloading method, drawing method, top pressing method, temperature difference method and destruction method.

1. Knock down method

That is, the impact energy generated by a hammer or other heavy object when it hits or hits the part is removed. Of course, this approach has both advantages and disadvantages.

The advantage is that the tool is simple, easy to operate, and does not require special tools and equipment. The disadvantage is that if the unloading method is not correct, the parts are easy to damage or destroy. This method is widely used and can be used for many parts. This way is more commonly used, of course, but also prone to some problems, so in the disassembly should pay attention to the following:

1) Pay attention to the strength according to the size, weight and firmness of the disassembly parts;

2) To take protective measures on the hit parts, usually use copper rod, bakelite rod, wood hammer wood, etc., to protect the shaft sleeve, sleeve hit wheel rim, etc.;

3) To test the unloading parts, the purpose is to investigate the combination of parts firmly, to test the direction of the parts.

4) The operator should pay attention to safety.

2. Drawing method

The drawing method should be used for parts with high accuracy that are not allowed to be knocked or cannot be disassembled by the removal method. It is disassembled with a special puller. This way also has advantages and disadvantages, the advantage is that the disassembly parts are not affected, disassembly is safer, not easy to destroy parts; The disadvantage is that special pullers need to be made. It uses high precision, parts that cannot be tapped and parts that cannot be tapped. In use, pay attention to whether the positioning fasteners on the shaft and sleeve are completely disassembled; Check the removal direction of the shaft; Prevent parts burr, dirt falling into the matching hole stuck parts; Do not need to replace the sleeve generally do not disassemble, to avoid the deformation of the disassembled parts, the replacement of the sleeve can not be arbitrarily punched, because the end will destroy the surface of the matching hole.

3. Top pressing method

Disassembly with tools and equipment such as spiral C-chuck, mechanical press, hydraulic press or jack. Suitable for interference fit with simple shape. In the machine repair and disassembly, many parts can not be disassembled on the press, and the application is relatively few.

4. Temperature difference method

This method can be used when the disassembly size is large, the fit interference amount is large, or the fit parts with large interference and high precision can not be disassembled by the method of hammer unloading or top pressing.

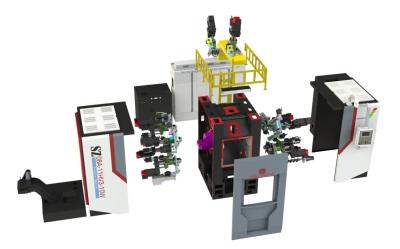

water wheel rotary transfer machine processing problems, which way to disassemble and repair it? figure

5. Sabotage

If it is necessary to disassemble the fixed connection such as welding and riveting, or the shaft and the sleeve bite each other, or destroy the accessory in order to save the main part, the destructive disassembly can be carried out by using the method of car, saw, chisel, drilling, cutting, etc. Such a way of application is small, and has a certain destructive, so it is generally not recommended to use.

water wheel rotary transfer machine https://www.zjshuangzheng.com/Integrated-Transfer-Machine.html