Categories

Tags

-

#Cummins Engine

#Cummins Engines

#Cummins Pump Drive Engine

#Applications of Cummins Diesel Engines

#Major Cummins Factories in China

#Cummins Engine Parts Dealer

#Cummins KTA19 Pump Drive Engin

#Cummins Six Cylinder Diesel Engines

#Cummins KTA19

#Cummins M11 Engine

#8.3 Cummins Engine

#Cummins

Archives

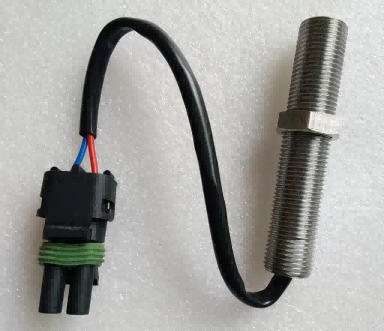

Understanding the Role of Cummins Diesel Engine Speed Sensor

-

Understanding the Role of Cummins Diesel Engine Speed Sensor

The speed sensor is a crucial component of any Cummins diesel engine. Often overlooked, this sensor plays a key role in monitoring engine RPM (revolutions per minute) and transmitting that information to the engine control unit (ECU). By providing accurate speed data, it ensures optimal fuel injection timing, engine performance, and emission control.

Why the Speed Sensor Is Important

Fuel Management: The ECU uses speed data to calculate fuel delivery. A faulty sensor can lead to poor fuel efficiency.

Engine Protection: Accurate RPM readings help prevent engine over-revving, protecting internal components.

Transmission Operation: On engines with automated or electronic transmissions, the speed sensor aids smooth gear changes.

Emission Control: Precise engine speed measurement ensures proper combustion timing, helping reduce harmful emissions.

Signs You May Need to Replace Your Speed Sensor

A failing Cummins diesel engine speed sensor can manifest in various ways:

Engine stalling or hesitation: The ECU may not get accurate RPM readings, causing irregular engine operation.

Check Engine Light: A common warning triggered by speed sensor errors.

Poor fuel efficiency: Incorrect RPM data can lead to over-fueling or under-fueling.

Transmission issues: Delayed or harsh gear shifts in electronic transmissions.

Replacement and Maintenance

Replacing a faulty speed sensor promptly avoids engine performance loss and prevents secondary damage. Always use genuine parts to maintain reliability and durability.

For genuine Cummins speed sensors and professional installation support, consider JOZ, a Cummins Authorized Dealer, offering high-quality products and expert guidance.