Is Centrifugal Blower by Cbbmachine Right for Industry?

-

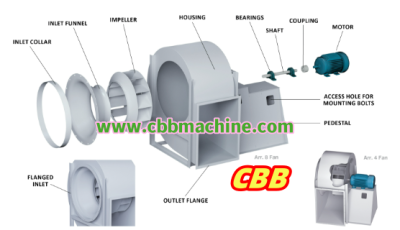

In industrial ventilation and material handling systems, the Centrifugal Blower engineered by Cbbmachine serves as a reliable source of controlled airflow for diverse processing environments. Designed to generate steady air pressure through rotational force, this equipment supports ventilation, dust extraction, drying processes, and pneumatic conveying. Its structure enables efficient air movement while maintaining stable operation within demanding production settings.

The working principle is based on the rotation of an impeller that draws air into the housing and redirects it outward through centrifugal force. As the air moves from the center toward the outer edges of the impeller, pressure increases, allowing the system to deliver consistent airflow to designated channels. This mechanism makes the blower suitable for applications requiring directed air movement rather than simple circulation.

Stable airflow is essential in many industrial processes. In manufacturing facilities, controlled ventilation contributes to temperature regulation and air quality management. In processing lines, directed air streams assist with drying coatings, cooling components, or transporting lightweight materials. By maintaining balanced pressure output, the blower helps ensure that each stage of production operates within its intended environmental conditions.

Structural integrity plays a vital role in long-term reliability. Carefully designed housings, balanced impellers, and durable bearings support smooth rotation and reduced vibration. This mechanical stability not only extends operational lifespan but also contributes to quieter performance in enclosed working spaces. Proper alignment between motor and impeller further enhances consistent airflow generation.

Adaptability is another significant advantage. Blowers can be configured to match varying airflow requirements across industries such as packaging, textile manufacturing, chemical processing, and environmental management. Different mounting orientations and ducting connections allow integration into both compact machinery and larger facility systems. This flexibility enables businesses to tailor airflow solutions to specific operational demands.

Energy efficiency remains an important consideration in modern production environments. By optimizing airflow pathways and minimizing internal resistance, well-designed equipment supports effective air movement without unnecessary energy consumption. This balance between performance and efficiency aligns with the growing emphasis on sustainable industrial practices.

Maintenance accessibility further enhances operational continuity. Thoughtful component layout allows for convenient inspection and servicing, helping reduce downtime during routine checks. Reliable performance, combined with practical upkeep, ensures that ventilation and airflow systems remain stable over extended production cycles.

In industries where environmental control directly influences productivity and safety, dependable airflow equipment becomes an integral part of the infrastructure. A carefully engineered blower does more than circulate air; it supports consistent working conditions and reinforces the efficiency of interconnected systems.

If you are considering how to strengthen airflow management within your facility, let curiosity guide you to https://www.cbbmachine.com/ , where detailed insights and tailored solutions are ready for your next step.