Categories

Tags

-

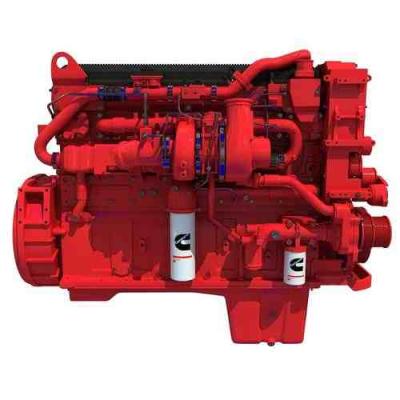

#Cummins Engine

#Cummins Engines

#Cummins Pump Drive Engine

#Applications of Cummins Diesel Engines

#Major Cummins Factories in China

#Cummins Engine Parts Dealer

#Cummins KTA19 Pump Drive Engin

#Cummins Six Cylinder Diesel Engines

#Cummins KTA19

#Cummins M11 Engine

#8.3 Cummins Engine

#Cummins

#M11 Cummins Engine

#Cummins Alternator

#Cummins Injector

#Cummins K19 Engine

#Cummins KTA19 Specifications

Archives

A Complete Guide to Cummins Level 1, 2, and 3 Maintenance

-

A Complete Guide to Cummins Level 1, 2, and 3 Maintenance

When operating heavy-duty Cummins engines, proper maintenance is the key to ensuring performance, reliability, and long service life. Cummins categorizes its service schedule into Level 1, Level 2, and Level 3 Maintenance. Each level has different service intervals and replacement parts involved. Let’s break down what they mean.

Level 1 Maintenance (Daily to Every 250 Hours)

Level 1 Maintenance is the most basic service, focusing on routine checks and fluid care. It is usually performed daily or at short intervals (up to 250 hours of operation).

Key tasks include:

l Checking oil levels and topping up if necessary

l Checking coolant levels and adding coolant if required

l Inspecting air filters (replace if restricted)

l Checking belts, hoses, and fluid leaks

Parts commonly replaced:

l Engine oil

l Oil filters

Level 2 Maintenance (Every 500–1,000 Hours or Quarterly)

Level 2 Maintenance involves a deeper inspection and replacement of consumables. It ensures that the engine continues to run efficiently without performance losses.

Key tasks include:

l Performing all Level 1 tasks

l Changing fuel filters

l Replacing crankcase ventilation filters (if equipped)

l Checking and tightening battery connections

l Inspecting turbocharger and intercooler for leaks

Parts commonly replaced:

l Oil filters

l Fuel filters

l Crankcase ventilation filter

Level 3 Maintenance (Every 2,000–4,000 Hours or Annually)

Level 3 Maintenance is the most comprehensive service and requires certified technicians. It involves both preventive and corrective actions to maximize engine life.

Key tasks include:

l Performing all Level 1 & 2 tasks

l Replacing coolant and coolant filters

l Inspecting and possibly replacing injectors

l Checking valve lash (adjustment if needed)

l Replacing air filters

l Inspecting alternator and starter motor

Parts commonly replaced:

l Coolant and coolant filters

l Air filters

l Injectors (if wear is found)

l Belts and hoses (if worn)

Conclusion

By following Cummins’ Level 1, 2, and 3 Maintenance schedules, operators can avoid costly downtime and extend engine lifespan. Staying consistent with scheduled service is an investment in both engine reliability and operational efficiency.