Categories

Tags

-

#Car Seat Cover Manufacturer

#Relief Valve Test Bench

#Boosting circulation pump

#Iron Padlock

#Kids Cosmetics

#Party Body Glitter

#Cordless PEX Crimping Tool

#Hydraulic Crimping Tool

#huge soup bowls

#salad bowl manufacturer

#Professional Kitchen Cookware Supplier

#Aluminum Skillet Manufacturer

#Multi Wing Fan Factory

#External Rotor Axial Fan

#outdoor distribution box

#CNC Lathe Mill

#Mass Air Flow Sensor

#Acetate Sunglasses

#Lip Gloss in Yiwu

#Composite Membrane

#Bathroom Floor Drains

#Flat Caps

#Radiator Mounting Bracket

#Photovoltaic Inverter Aluminum Die Casting Parts

#Custom Metal Mold

#Custom Metal Mold Manufacturer

#kitchen tools and utensils

#Customizable Satisfactory Cap

#Led table tree light

#linear shafts

#Solid Steel Needles

#Wholesale Elastic Straps

#Expanding Gate Valve

#Hard Seal Ball,

#Liquid Cooled Temperature Control System

#Surge Wave Pond Aerator

#Insulated coffee mugs

#Precision Gear Motor

#Headband

#Regulating Valve casting

#Rubbish Bag Blown Film Machine

#nano black kitchen sink

#machine-made sink

#Custom Hair Claws Clips Manufacturer

#Trend Hair Accessories Manufacturer

#Plastic Body Foodcontainer

#Diaphragm Pump

#Customized Diaphragm Pump Manufacturers

#Erasable gel pens

#Precision Stamping Mold Company

#Diaphragm Pump Manufacturer

#padlock

#Wholesale High Quality Padlock

#Veterinary Needles

#Veterinary Supplies

#PVC Marble Wallpaper

#PVC Marble Wallpaper Manufacturers

#Electric Enclosed Vehicle

#Self tapping metal screws

Archives

Your Guide to a Custom Metal Mold Manufacturer

-

If you're developing a product that requires metal components, you've probably encountered the term Custom Metal Mold. But what does getting one actually involve, and how do you navigate the process of selecting a partner for the job? Let's look at this from a practical standpoint, much like you would when sourcing any other critical tool.

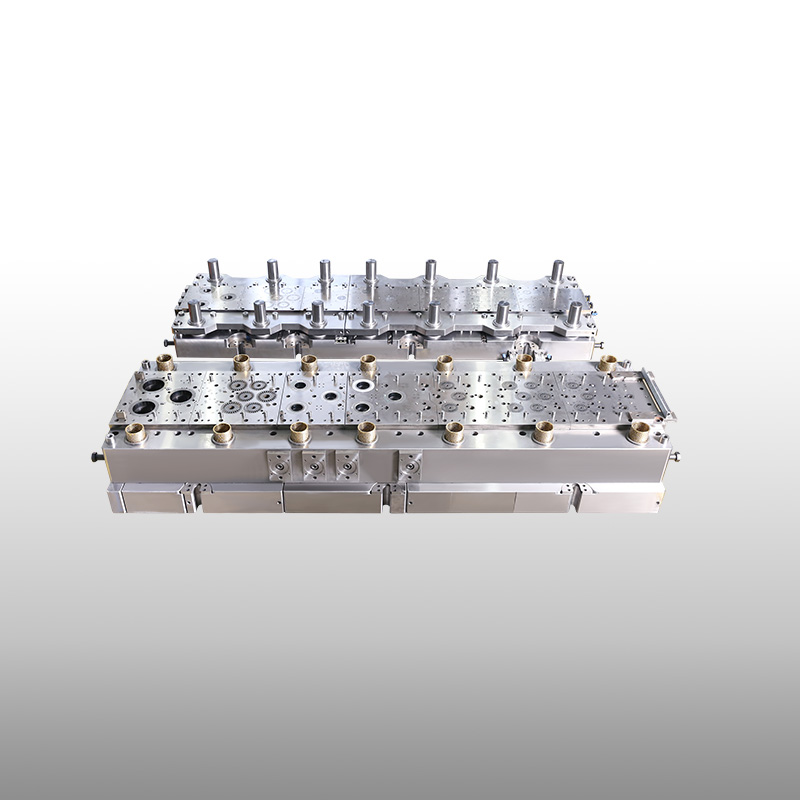

A Custom Metal Mold is a tool, often made from hardened steel or aluminum, that shapes molten metal into a specific part design under high pressure. This is common in processes like die casting or injection molding. The "custom" aspect means the mold is designed and built from the ground up for your component, rather than being a standard, reusable block. This is where a capable Custom Metal Mold Manufacturer becomes essential. They translate your part drawings into a functional, durable tool. A strong manufacturer won't just take your order; they will review your design for potential issues like undercuts or wall thickness variations that could complicate production. This collaborative design phase is a core part of the value that a good Custom Metal Mold Manufacturer provides.

So, what should you consider when looking for a partner? Experience with your specific industry and material is a logical starting point. A Custom Metal Mold for a high-volume automotive part will have different requirements than one for a delicate, low-run aerospace component. Discuss your production goals openly. A reputable Custom Metal Mold Manufacturer will ask about your expected output, material choice, and quality standards to propose a mold that balances performance with cost. They might suggest a more durable steel for a long-running project or a lower-cost aluminum for prototyping. This guidance is part of the service that extends beyond simple fabrication.

The result of this partnership is a tool made for your needs. A well-crafted Custom Metal Mold can contribute to smoother production runs, fewer defective parts, and a more efficient manufacturing cycle. It's an investment in the foundation of your product. By working with a knowledgeable Custom Metal Mold Manufacturer, you gain a partner who helps navigate the technical complexities, turning your part design into a tangible, high-quality reality.

Specification Parameters

Comprehensive life: ≥160 million punches Blade die life: ≥5 million strokes/0.1mm Mold structure: Three-plate mold base + ball guide Effective cutting edge height: ≥8mm Blade material: DJ40 Grooved die form: Punch grooved die, slow wire finishing, the punch is polished using a special process to remove the oxidation layer Guide parts: Precision + high hardness Blanking speed during running-in period: 80-280 punches/minute Blanking speed: 280-300 punches/minute Concentricity: ≦0.05mm Protection device: Equipped with misfeed protection device Punching burr: ≦0.05mm Riveting force: 30N Safety device: Misfeed detection + equal height limit column Product output form: Conveyor belt

Rotor control device

Chute control devicePlate control device: Cylinder Mold base material: Upper and lower mold seats P20, middle unloading seat P20, the second and fourth levels are made on the same set of molds and are interchangeable during production. The shaft hole can be used for three interchangeable pumping plates. Spare parts provided: 30% of wearing parts Internal plate material: Cr12MOV https://www.motorcoremold.com/product/