Categories

Tags

-

#electric tailgate

#flexible packaging

#Mesh Tarps

#Vegetable Processing Line

#Invest in Vegetable Processing

#Benefits of Vegetable Processing

#Vegetable Processing Industry Trends

#Anti Drone Guns

#Law Enforcement

#Drone Management

#Public Safety

#CNC Milling Machines

#Metalworking Efficiency

#Precision Manufacturing

#Automated Milling Solutions

#Hand Flags for Sports Events

#Sports Fan Hand Flags

#Team Spirit Hand Flags

#Event-Ready Hand Flags

#Powerwall for Home Energy Needs

#Powerwall Key Features

#Home Energy Storage Solutions

#Sustainable Home Energy

#Powerwall Backup Power

#How to Choose a Sports Sweatband That Fits Your Activity? Expert Tips for Maximum Comfort & Performance

#smart tailgate

#power liftgate

#automatic liftgate

#hands free power tailgate

#aftermarket power tailgate

#car electric tailgate

#auto tailgate

#Custom Packaging for Branding

#Brand-Boosting Custom Packaging

#Custom Packaging for Business Growth

#High-Quality Custom Packaging

#Brand Loyalty via Custom Packaging

#White Cardboard Packaging

#Eco-Friendly White Cardboard

#White Cardboard Uses

#zhenfeng White Cardboard

#Packaging Industry Essentials

#High-Quality Fresh Coffee Vending Machine

#Barista-Grade Fresh Coffee Vending

#Commercial Coffee Vending Machine for Fresh Brews

#Easy-Maintain High-Quality Coffee Vending

#Office Fresh Coffee Vending Solution

#Japan Style T-shirts

#Daily Fashion T-shirts

#Japanese Aesthetic Clothing

#Casual Japan-Inspired Tees

#Everyday Stylish T-shirts

#Reliable Voltage Stabilizer for Sensitive Devices

#Voltage Stabilizer for Lab Equipment

#Sensitive Device Voltage Protection

#High-Quality Voltage Stabilizer

#Industrial Voltage Stabilizer

#Fixed Installation LED Display

#Permanent LED Display Solutions

#Durable Fixed LED Display

#High-Performance LED for Permanent Setups

#Reliable Fixed Installation Display

#Auto Scraper Centrifuge

#Efficiency Improvement Methods

#Centrifuge Performance Boost

#Industrial Centrifuge Optimization

#Auto Scraper Centrifuge Cost Reduction

#Beginner Bodybuilding Equipment

#Essential Fitness Gear for Newbies

#Starter Bodybuilding Tools

#Budget-Friendly Fitness Equipment

#Food Storage

#Sustainable Food Packaging

#Freshness-Preserving Packaging

#Food Business Packaging Solutions

#MS Sealant for Interior Design

#High-Performance MS Sealant

#Interior Decoration Sealant Advantages

#Eco-Friendly MS Sealant

#MS Sealant Application Tips

#Peptide raw powder

#Pharmaceutical water system

#Small scale Peptide production line package

#Sterilizing system

#Vial Compact Line for Washing

#production line

#bathroom dividers

#plastic pelletizing

#vacuum circuit breaker

#Outdoor Dining Set

#3D Printing

#tv cabinet

#cleaning towel

#Eco-Friendly Roller Blinds Fabric

#Roller Blinds Fabric Benefits

#Sustainable Window Coverings

#Green Roller Blinds Fabric

#High-Quality Roller Blinds Fabric

#Bag in Box Packaging

#Sustainable Liquid Packaging

#Bulk Liquid Container

#Eco Friendly Packaging Solution

#Master Bunny Factory Apparel

#Master Bunny Factory Clothing Line

#Master Bunny Casual Wear

#Master Bunny Durable Apparel

#Decanter Centrifuge

#Daily Maintenance Points for Decanter Centrifuge

#Centrifuge Lifespan Extension

#Decanter Centrifuge Fault Prevention

#Curved LED Screen

#Custom Curvature LED Screen

#Space-Fit LED Display

#Unique Space LED Screen

#Precision Engineering

#Manufacturing Technology

#CNC Technology

#Meat Tenderizers

#Innovations in Meat Tenderizers

#Advanced Meat Tenderizers

#Eco-Friendly Meat Tenderizers

#Truck Tarps

#Load Security

#Cargo Protection

#Transportation Safety

#Laser Cutting Nozzles

#Material Efficiency

#Precision Cutting

#Waste Reduction

Archives

Daily Maintenance Points for Decanter Centrifuge

-

Posted by HitokaCece HitokaCece Filed in Other #Decanter Centrifuge #Daily Maintenance Points for Decanter Centrifuge #Centrifuge Lifespan Extension #Decanter Centrifuge Fault Prevention 282 views

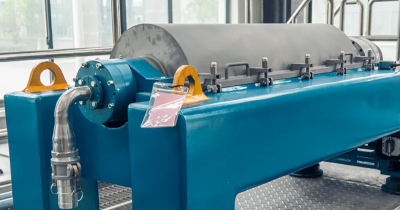

Think about this: You rely on your Decanter Centrifuge to keep sewage treatment or industrial separation running smoothly. Then one morning, it grinds to a halt—parts worn out, sludge buildup jamming the drum, and a repair bill that makes you wince. Sound like a nightmare? It’s one too many plant managers face, and it almost always comes down to skipped daily maintenance. A Decanter Centrifuge is like a high-performance car: it needs regular checks to stay in top shape, not just fixes when it breaks. Today, we’re sharing the critical daily maintenance points that keep your centrifuge running reliably, cut down on unexpected repairs, and help it last for years. Whether you’re new to managing this equipment or looking to refine your routine, these tips will turn maintenance from a chore into a safeguard for your operations.

Drum Cleaning for Daily Decanter Centrifuge Maintenance

The drum is the “workhorse core” of your Decanter Centrifuge—if it’s clogged with sludge or residue, the whole machine slows down or stalls. Yet many teams skip daily drum cleaning, thinking “a little buildup won’t hurt.” But here’s the truth: Even a thin layer of dried sludge on the drum wall throws off its balance. Over time, that imbalance causes extra vibration, wears out bearings faster, and makes the motor work harder (wasting energy).

Daily cleaning doesn’t have to be complicated. After each shift, run clean water through the drum for 10-15 minutes—this flushes out leftover sludge, especially from the small gaps between the drum and the screw conveyor. For sticky residues (like those from food processing or chemical effluent), add a mild, non-corrosive cleaner to the water—just check the centrifuge’s manual to make sure the cleaner is compatible. A wastewater plant once skipped this step for a week; the drum got so clogged that it took 8 hours of intensive cleaning to fix, plus a $500 replacement for a damaged screw. Don’t let that happen—spend 15 minutes daily on drum cleaning. It’s the simplest way to keep your Decanter Centrifuge’s “heart” beating strong.

Lubrication Checks for Decanter Centrifuge Daily Upkeep

If the drum is the heart, lubrication is the “blood” that keeps your Decanter Centrifuge’s moving parts working smoothly. Dry or dirty lubricant is like putting sand in a bike chain—it causes friction, overheating, and premature wear. The most critical parts to lubricate daily are the drum bearings and the screw conveyor’s drive shaft—these parts handle the most stress during operation.

Start by checking the lubricant level in the bearing housing: it should sit at the middle of the sight glass (never below or above). Next, inspect the lubricant’s condition—if it’s cloudy, discolored, or has debris, drain it and refill with fresh lubricant (use the type specified in the manual). A technician once found black, gritty lubricant in a centrifuge’s bearings; by the time they replaced it, the bearings were already scored, costing $1,200 to fix. Here’s a pro tip: Keep a log of lubrication checks—note the date, level, and condition. This helps you spot trends (like lubricant getting dirty faster) that might mean another issue (like a leaking seal). Daily lubrication checks take 5 minutes, but they save you from expensive part replacements down the line.

Electrical System Inspection for Daily Decanter Centrifuge Care

The electrical system is the “nervous system” of your Decanter Centrifuge—even a small loose wire or a dirty sensor can cause big problems, from erratic operation to complete shutdowns. Many teams overlook electrical checks because they seem “too technical,” but basic daily inspections are easy and essential.

First, check the control panel: Make sure all indicator lights work, and the display shows no error codes. Wipe down the panel with a dry cloth to remove dust—dust buildup can cause overheating of internal components. Next, inspect the power cables and connections: Look for frayed wires, loose terminals, or signs of overheating (like discolored plastic). A food processing plant once had a loose cable that caused the centrifuge to shut off mid-run, spilling 500 liters of wastewater and requiring a full cleanup. Finally, test the emergency stop button—press it to make sure the centrifuge shuts down immediately. This simple test could prevent accidents if there’s an emergency. Daily electrical checks take 10 minutes, but they keep your Decanter Centrifuge’s “nerves” working reliably.

Abnormal Vibration and Noise Monitoring for Decanter Centrifuge

Vibration and noise are like your Decanter Centrifuge’s “voice”—they tell you when something’s wrong. A well-running centrifuge makes a steady, low hum; any sudden increase in vibration or unusual noises (like grinding, squealing, or thumping) is a red flag. Yet many operators get used to “normal” vibration and ignore small changes—until the machine breaks.

Daily monitoring is straightforward. Before starting the centrifuge, place your hand on the drum housing—you should feel only slight, even vibration once it’s up to speed. If the vibration is uneven or stronger than usual, stop the machine and check for issues: a misaligned drum, loose bolts, or sludge buildup. For noise, listen carefully during operation—use a sound level meter if you have one, but even your ears can pick up odd sounds. A chemical plant operator noticed a faint grinding noise; they shut down the centrifuge and found a small metal fragment in the drum—fixing it took 30 minutes, versus hours of damage if they’d ignored it. Make vibration and noise checks part of your startup routine. It’s a simple way to catch problems early, before they turn into costly downtime.

Conclusion

Daily maintenance for your Decanter Centrifuge isn’t a hassle—it’s an investment in reliability, longevity, and cost savings. From cleaning the drum to keep its core running smooth, to lubricating moving parts to prevent friction, to inspecting the electrical system and monitoring vibration—each small step adds up to a machine that works when you need it. Skipping these points might save time today, but it leads to expensive repairs, unexpected downtime, and a shorter lifespan for your centrifuge.

A well-maintained Decanter Centrifuge doesn’t just run longer—it runs more efficiently, using less energy and delivering consistent separation results. For plant managers and technicians, that means smoother operations, lower costs, and less stress. Think of daily maintenance like watering a plant: it’s a small daily effort that leads to long-term growth and health. By following these simple points, you’ll protect your investment and keep your Decanter Centrifuge as a reliable workhorse for years to come.