Categories

Tags

-

#Waste Oil to Base Oil Plant

#Well Control Simulators

#HFO Visbreaking

#Transformer Oil BDV Tester

#VR Emergency Training Simulator

#SF6 Gas Purification Machine

#Laser Cleaning

#Automatic Laser Welder

#Benchtop Pneumatic Dot Peen Markers

#Oil Well Work

#Portable Well Control Simulators

#well logging

#Petroleum Engineering

#virtual reality emergency training simulator

#Well Control Simulator

#Waste Oil to Base Oil Plants

#Portable Simulator

#Web Guide Systems

#Floating Rig

#Turbine Oil Filtration

#Land Rig Installation

#Clothes Drop Boxe

#Industrial Garbage Compactor

Archives

Future Development Trends in Industrial Garbage Compactor Syste

-

Industrial garbage compactors have long been stalwarts of waste management, providing brute-force efficiency. However, the future of this equipment is being shaped by digital innovation, sustainability demands, and smarter automation. The next generation of compactor systems will be more connected, efficient, and integrated than ever before. Let's explore the key development trends on the horizon.

Integration of IoT and Smart Monitoring

The Internet of Things (IoT) is revolutionizing industrial equipment, and compactors are no exception. Future systems will be equipped with an array of sensors and connectivity features.

These smart compactors will monitor fill levels, compaction cycles, maintenance needs, and operational status in real-time. Data will be transmitted to a centralized cloud platform or facility management software, enabling predictive maintenance to prevent downtime. Managers will receive automated alerts when a container is full, optimizing collection routes and schedules for maximum efficiency and cost savings.

Enhanced Energy Efficiency and Alternative Power

As industries push for net-zero goals, the energy consumption of equipment comes under scrutiny. Future compactor development will focus heavily on reducing electrical demand through more efficient hydraulic systems, regenerative circuits, and high-efficiency motors.

Furthermore, we can expect a greater adoption of alternative power sources. Solar-powered compactors for outdoor use or systems designed to integrate with on-site renewable energy will become more common. The aim is to minimize the carbon footprint of the waste compaction process itself.

Advanced Material Recognition and Sorting

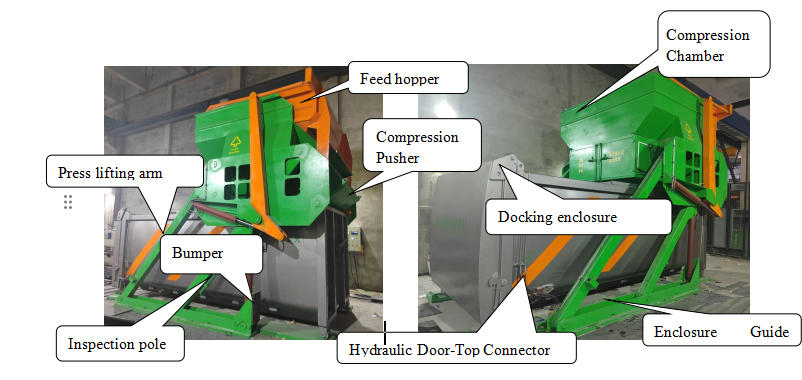

While today's compactors often handle pre-sorted streams, future systems may incorporate rudimentary sorting at the point of compaction. Using technologies like optical sensors, AI-powered vision systems, and even robotic arms integrated with the compactor feed hopper, these advanced systems could identify and separate different material types.

This could mean automatically diverting recyclables from landfill waste or compacting different materials into separate chambers. This trend points toward more automated, closed-loop waste handling stations within industrial facilities.

Improved Durability with Advanced Materials

To withstand harsher environments and increase longevity, future compactors will utilize advanced materials. This includes the use of higher-grade, corrosion-resistant steels, wear-resistant liners, and composite materials for certain components.

Additionally, self-lubricating systems and sealed hydraulic units that require less maintenance will become standard. The focus will be on creating "set-and-forget" systems that offer greater reliability and a lower total cost of ownership over their extended lifespan.

Focus on Safety and Ergonomic Design

Safety will remain a paramount concern, driving design innovations. Future trends include enhanced safety interlocks, light curtains, and proximity sensors that completely prevent operation if a person is detected in a danger zone.

Ergonomics will also be key, with improved user interfaces, remote control operation, and designs that minimize the need for manual feeding or contact with the machine. The goal is to create a safer, more user-friendly interaction between personnel and powerful compaction equipment.

Conclusion

The future of industrial garbage compactor systems is intelligent, sustainable, and seamlessly integrated. By embracing IoT, AI, green energy, and advanced engineering, these evolving machines will transition from being simple volume-reduction tools to becoming intelligent nodes in a facility's resource management ecosystem, driving efficiency, sustainability, and safety to new levels.