Categories

Tags

-

#Drum Pilling Tester Operation Process and Precautions

#Bag Loading Machine Supplier: Creating Efficient and Accurate Packaging Solutions

#From Wardrobe to Suitcase: Multi Scenario Application of Yibo Clothes Dust Cover

#The Role of Changhong Precision in Injection Molding Manufacturing Processes

#SLENERGY Intelligent Energy Management Platform: Efficient Energy Saving

#Smart Life

#Large Flow Low Noise Blower: The Silent Revolution in the Industrial Field

#Industrial Field: The Importance and Application of SWT Automatic Backup Generators

#The Importance and Challenges of Plastic Pigments in Industry

#The Brush Mower Helps with Farmland Management

#Improves Efficiency and Environmental Protection

#High Quality Fit for TOYOTA 4K-E Piston Rings: Balancing Durability and Performance

#Application of Tube Skid Container in the Energy Industry

#The Role of Rail Dowels in Preventing Track Deformation and Ensuring Safety

#Application of Recyclable Materials in Shaped Spout Pouches

#Real-Time PCR Analyzer: A Powerful Tool for Real-Time Monitoring of Gene Expression

#The Performance and Practicality of Power Puzzle DS1601H

#Exploring the Advantages and Applications of Sea-Rail Service

#Green tea / cotton yarn

#Improving Efficiency: Advantages of Spiral Tunnel Ice Cream Machine

#Paging Labeling Machine Helps Enterprises Achieve Intelligent Packaging Upgrade

#How 4-Way Priority Valve Controller Can Improve Industrial Automation Efficiency

#Revolutionizing Gas Metal Arc Welding (GMAW): Advanced Welding Positioner Integration for Enhanced Productivity

#Wuxi Bluemann Made a Brilliant Appearance at SNEC PV+2025

#And the Exhibition Came to a Successful Conclusion

#Lightweight and Sturdy: Advantages of Aluminum Alloy Camera Hou

#Customized OEM Milling Cutter Bar: Meeting Diverse Machining Needs

#Yuantai Provides Clean Energy for Somalia: Transportation of Solar Photovoltaic Panels

#ELP Global Shutter USB Camera Module

#Suitable for Multiple Platforms

#DPA Paint Mist Filter Cotton / DPA Paint Mist Filter Bags

#Performance and Advantages of BAN Panel Air Filter

#Wash out Personality: Diversified Functions of Professional Denim Washing Machine

#Incubator for Water Analysis: A Tool for Accurately Controlling Water Quality Safety

#Exploring the Diversity and Applications of LED Indicator Lights

#Analysis of Technical Characteristics and Advantages of Side Plate Vibration Motor

#New Choice for Architectural Lighting: Advantages and Applications of Construction Light Tower Generator

#Low Vibration Brushless Adjustable Fan: Technology Saves Energy

#Brings Fresh Fashion to Life

#Iron Zinc Chrome Brown: A New Material to Improve Coating Durability

#Lightweight Vacuum Cleaner Travel Vac B-C: A New Choice for Cleaning During Travel

#Revolution in the Pharmaceutical Industry: Advantages Brought by Automatic Labeling Machines

#Celebrating Dragon Boat Festival

#HENGXING Joins Hands to Share Traditional Culture

#Advantages and Applications of Excavator Universal ClawWeld

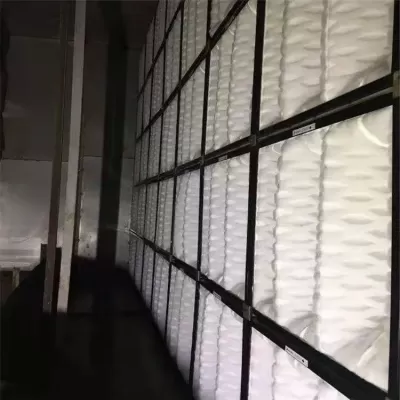

#Electrostatic Filter Cotton: Technical Overview

#Inspectores de la Provincia de Jiangxi Visitan Sanxin Medtec Co.

#Ltd y Llevan a Cabo Actividades de Formación Práctica in Situ Sobre Productos Sanitarios

Archives

Electrostatic Filter Cotton: Technical Overview

-

1. Working Principle

Electrostatic filter cotton utilizes electrostatic attraction to capture airborne particulate matter, significantly enhancing filtration efficiency through charged fiber media.

2. Performance Advantages

- Enhanced Filtration: Capable of trapping sub-micron particles (superior to mechanical filtration)

- Energy Efficiency: Low airflow resistance (typically 30-50% lower than HEPA filters)

- Reusability: Washable designs allow 15-20 cleaning cycles (varies by manufacturer)

- Economic Benefit: 60-70% cost reduction compared to disposable filters over 3-year lifecycle

3. Technical Limitations

- Maintenance Requirements:

- Monthly cleaning recommended for optimal performance

- 15-20% efficiency degradation after each wash cycle

- Environmental Sensitivity:

- Relative humidity >70% reduces electrostatic effect by 40-60%

- Ozone emission <0.01 ppm (meets UL867 standards)

4. Industrial Applications

- Commercial Air Purification:

- MERV 11-13 equivalent (per ASHRAE 52.2)

- Particulate capture down to 0.3μm @ 85-95% efficiency

- Cleanroom Technology:

- ISO Class 5-7 environments

- Compliant with FDA 21 CFR Part 11 for pharma applications

- Industrial Process Filtration:

- Powder coating booths: 99% capture of 5-20μm particles

- Laser cutting fume extraction

5. Material Specifications

- Base Material: Polypropylene/polyester hybrid fibers

- Surface Charge Density: 10-15 μC/m²

- Typical Thickness: 10-25mm

- Operating Temperature Range: -30°C to 80°C

6. Comparative Performance Data

| Parameter | Electrostatic Cotton | Mechanical Filter |

|------------------|----------------------|-------------------|

| Initial Efficiency | 85%@0.3μm | 65%@0.3μm |

| Pressure Drop | 25Pa @ 2.5m/s | 45Pa @ 2.5m/s |

| Service Life | 3-5 years | 6-12 months |

| Energy Savings | 30-40% | Baseline |

Note: All performance data based on standard test conditions (25°C, 50% RH)

https://www.amdfil.com/electrostatic-filter-cotton-technical-overview.html